Categories

-

HVAC&R Controllers

- Indicators

- General Controllers

- Controllers for Refrigeration

- Controllers for Air-conditioning / Chillers

- Controllers for Cold Rooms

- Controllers for Humidity

- Controllers for Telecom

- Process Controllers

- Protection and Alarm Devices

- IOT Solutions

- Probes and Sensors

- HVACR Electrical Panel

- Industrial Automation

-

Valves and Controls

- Castle CFC/HCFC

-

Castle Ammonia

- Liquid Level Controller

- Shut Off Valves

- Solenoid Valves

- Safety Relief Valves

- Double Stop Valves

- Purge Valves

- Strainer

- Liquid Level Indicator

- Liquid Level Switch

- Check Valves / Stop cum Check Valves

- Overflow Valves

- Humidifier

- Angle Shutoff Valves(ODS)

- Ball Valves

- Stop Needle Valves

- Hand Regulating Valves

- Inline NRV

- Accessories for Cold Room

- Humidifier

Pilot Operated Solenoid Valve

This high side pressure instantly overcomes the bulb pressure and supplements the valve spring, immediately closing the port of the expansion valve.

Pilot Operated Solenoid Valve

Pilot Operated Solenoid Valve

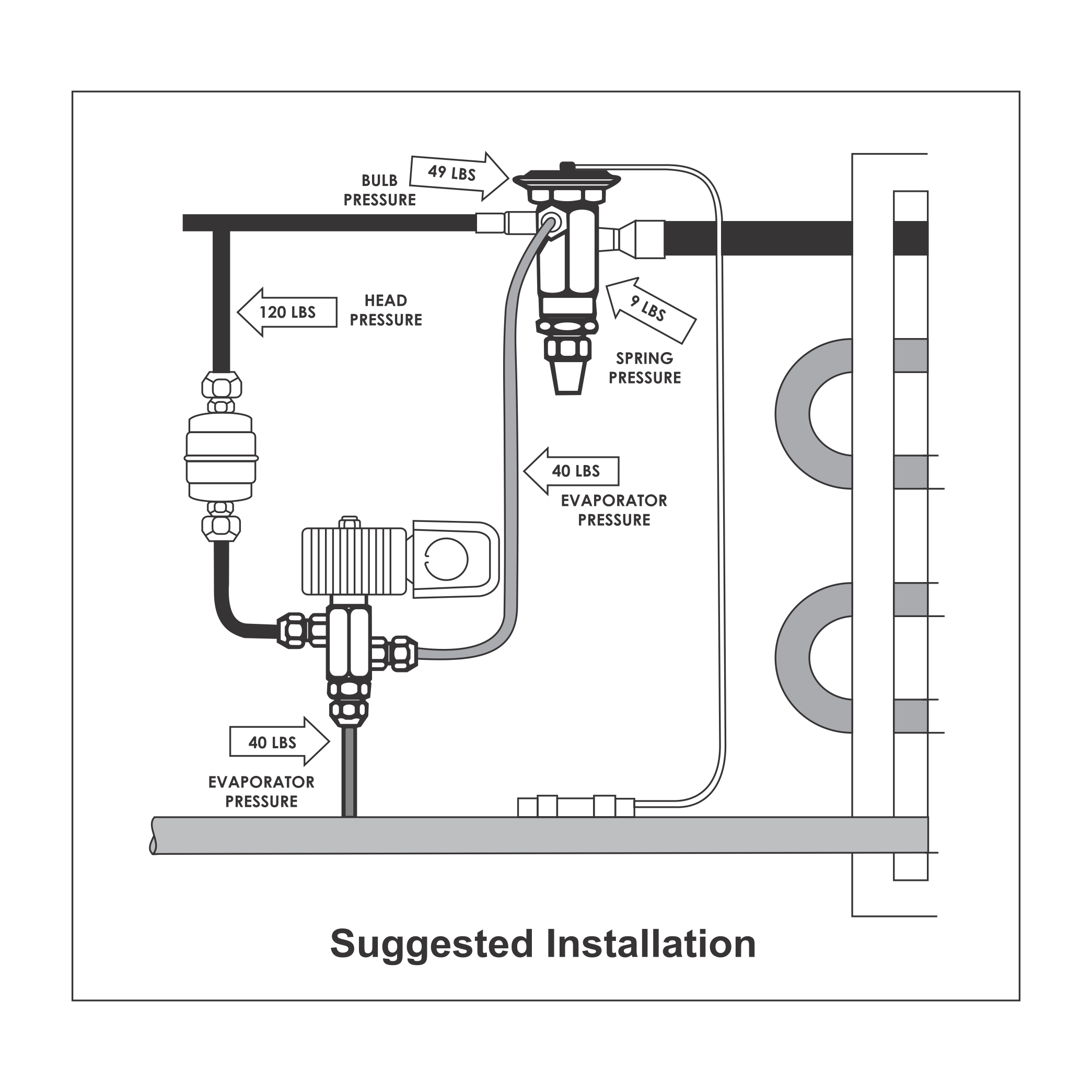

| Princples of Opration | The principle upon which the 180 Solenoid Pilot Control influences the expansion valve action is by the creation of a pressure under the valve diaphragm which is higher than the bulb pressure. This is how it is accomplished.

The type 180 has two parts, both in the valve body-one high pressure and one low pressure. When the solenoid coil is energized, the plunger moves upward sealing off the high pressure port. With the high pressure excluded from the pilot control, true suction pressure acts on the underside of the expansion valve diaphragm through the equalizer line and the low pressure port.

When the solenoid coil is de-energized, the low pressure port is closed, thereby closing the equalizer line from the valve to the suction line. The high pressure port is open and liquid line pressure is applied to the underside of the thermostatic expansion valve diaphragm. |

| Application | The type 180 Solenoid Pilot Control suitable for all refrigerants except Ammonia The 180 Solenoid Pilot Control is applicable for CFC & HCFC as a supplementary device to Thermosatic Expansion Valves. It is used in place of capacity solenoid valves for positive shut-off of liquid lines. The Solenoid Pilot Control does not directly close the liquid line, but acts on the thermostatic expansion valve causing the expansion valve to close. The 180 is installed in the external equalizer line of the thermostatic expansion valve, and has a third 1/4 “connection from the liquid line. |

© 2021. All Rights Reserved. | Developed By Illusions Brand Solutions